Mosebetsi oa ho roala le litšobotsi tsafilimi e koahetsoeng esale peleindastering ea khatiso li bohlokoa haholo. Lamination e bolela ho koahela bokaholimo ba taba e hatisitsoeng ka afilimi ea lamination ea mochesoho fana ka tšireletso, ho matlafatsa ponahalo le ho ntlafatsa boleng ba taba e hatisitsoeng. Tse latelang li tla hlahisa ka ho qaqileng mosebetsi oa ho roala le litšobotsi tsafilimi e koahetsoeng esale peleindastering ea khatiso.

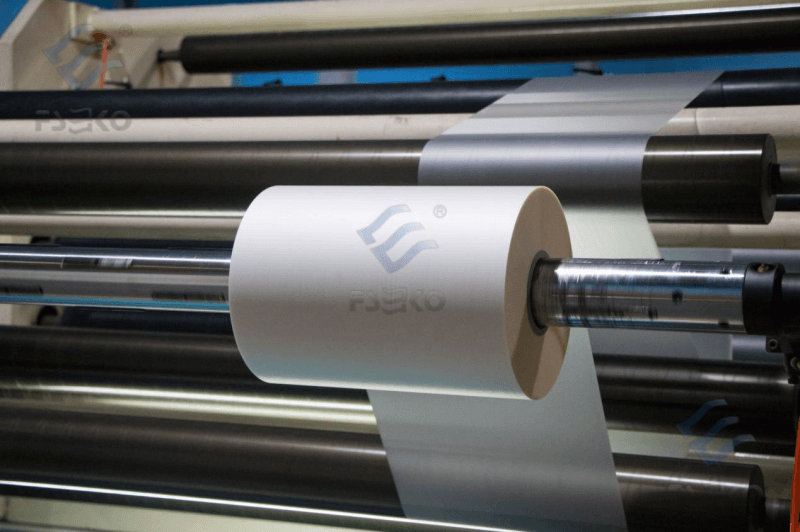

Mosebetsi oa ho roala oafilimi ea mocheso oa laminationhaholo-holo e kenyelletsa ho sireletsa taba e hatisitsoeng le ho ntlafatsa ho tšoarella. Ka ho laminating, lintho tse hatisitsoeng li ka sireletsoa ka katleho ho tloha ho mengoapo, tšilafalo le mahlaseli a UV, ho lelefatsa bophelo ba tšebeletso ea taba e hatisitsoeng. Ntle le moo, lamination e ka boela ea ntlafatsa ho hanyetsa metsi, ho hanyetsa abrasion le k'hemik'hale ea lik'hemik'hale tsa taba e hatisitsoeng, le ho ntlafatsa ho tšoarella le ho sebetsa ha taba e hatisitsoeng.

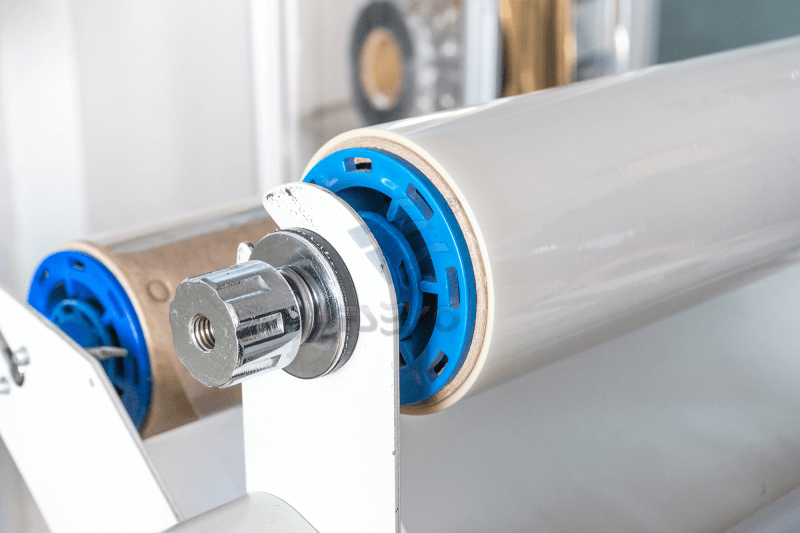

Litšobotsi tsa ho roala tsafilimi ea lamination ea mochesokenyeletsa mefuta-futa, tshireletso ya tikoloho le bokgoni bo phahameng.Thermal laminating filimie ka fana ka litlamorao tse fapaneng tsa kalafo ea holim'a metsi ho fihlela litlhoko tsa mokhabiso oa taba e hatisitsoeng e fapaneng, joalo ka matte, glossy, metallized, joalo-joalo. Ka nako e ts'oanang, boleng bo holimo.filimi e koahetsoeng esale peleli na le litšobotsi tsa tlhahiso e tlase ea "volatile organic compound" (VOC), ho senyeha le ho sebelisoa hape, le ho fihlela litlhoko tsa ts'ireletso ea tikoloho. Ho phaella moo, mokhoa oa ho roala oafilimi ea lamination ea mochesoe bonolo ebile e sebetsa hantle, e ka ntlafatsang katleho ea tlhahiso ea khatiso le ho fokotsa litšenyehelo tsa tlhahiso.

Ka kakaretso, mesebetsi ea ho roala le litšobotsi tsafilimi e koahetsoeng esale peleindastering ea khatiso e kenyelletsa ho sireletsa lintho tse hatisitsoeng, ho ntlafatsa ponahalo, ho ntlafatsa ho tšoarella, mefuta-futa, ts'ireletso ea tikoloho le bokhoni. Ka lamination, re ka fana ka tšireletso e betere le litharollo tsa mokhabiso bakeng sa taba e hatisitsoeng ho khahlametsa tlhokahalo e ntseng e eketseha ea 'maraka ea boleng ba taba e hatisitsoeng le ponahalo. Ka tsoelo-pele e tsoelang pele ea theknoloji ea khatiso le tlhokahalo ea 'maraka e fetohang, mosebetsi oa ho roala le litšobotsi tsafilimi e koahetsoeng esale pelee tla tsoela pele ho ntlafatsoa le ho ntlafatsoa, e fana ka litharollo tse molemonyana bakeng sa indasteri ea khatiso.

Nako ea poso: Aug-27-2024